|

model/parameter |

lab usage |

production usage |

|||||

|

nti-dzl-54w |

nti-dzl-98w |

nti-dzl-243w |

nti-dzl-300w |

nti-dzl-400w |

nti-dzl-720w |

||

|

working size |

mm |

300×300×600 |

350x350x800 |

450×450×1200 |

500×500×1200 |

500×500×1600 |

600×600×2000 |

|

control process |

|

thyristor control |

|||||

|

heating type |

/ |

graphite resistance heating |

|||||

|

ht zone capacity |

l |

54 |

98 |

243 |

300 |

400 |

720 |

|

loading weight |

g |

ht zone capacity × density (g/cm³)×1000 remark:1l=1000cm³ |

|||||

|

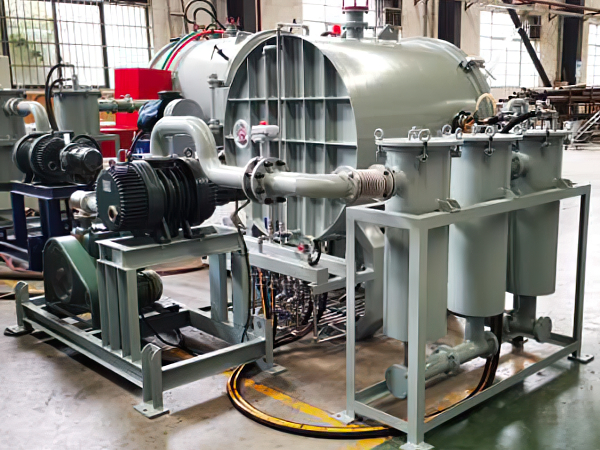

ultimate vacuum |

pa |

20 |

|||||

|

if power |

kw |

100 |

200 |

210 |

240 |

270 |

378 |

|

heating zone |

zone |

1 |

3 |

3 |

3 |

3 |

3 |

|

max. working temperature |

℃ |

2300 |

2300 |

2300 |

2300 |

2300 |

2300 |

|

usual working temperature |

℃ |

2200 |

2200 |

2200 |

2200 |

2200 |

2200 |

|

temperature unifomity |

℃ |

±5 |

±5 |

±5 |

±5 |

±5 |

±5 |

|

working environment |

/ |

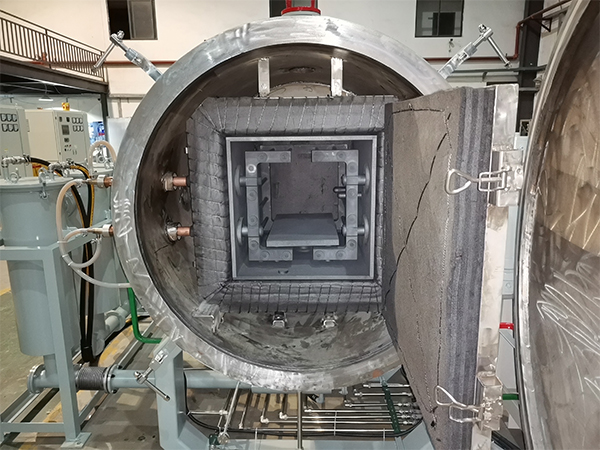

vacuum or argon atmosphere protection( micro positive pressure) |

|||||